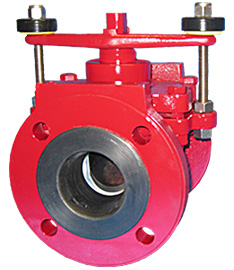

Model 790 Lined Plug Valve

ChemValve is a manufacturer of high performance, extended life (on average two times the life of other valves); fully lined plug and ball check valves that can be tailored to your specific application needs. The ChemValve Fully Lined Plug Valves include the models 790EB-150, the 790EB-300, and the 790EB-150/300 Double Block and Bleed (DBB). These valves are manufactured in sizes 1” thru 8” to accommodate many pipe line sizes.

ChemValve’s 790EB is an excellent choice for corrosive and/or corrosive plus abrasive applications due to its adjustability and flexibility of design. Unlike a Fully Lined Ball Valve design, the lined plug valve can be adjusted to stop a leak past the seats while the valve is in service and without line interruption by tightening down the packing flange. Furthermore, the adjustment is designed in a way it can be performed by a plant operator armed with a pair pliers. The packing flange extends perpendicular to the pipeline allowing easy adjustment of the packing flange nut especially if the valve is actuated because it normally extends beyond the actuator mounting bracket granting easy access.

ChemValve’s 790EB is an excellent choice for corrosive and/or corrosive plus abrasive applications due to its adjustability and flexibility of design. Unlike a Fully Lined Ball Valve design, the lined plug valve can be adjusted to stop a leak past the seats while the valve is in service and without line interruption by tightening down the packing flange. Furthermore, the adjustment is designed in a way it can be performed by a plant operator armed with a pair pliers. The packing flange extends perpendicular to the pipeline allowing easy adjustment of the packing flange nut especially if the valve is actuated because it normally extends beyond the actuator mounting bracket granting easy access.

One of the unique features of our fully lined plug valves is the field replaceable seats. These seats are replaceable while they are in the pipe line in the field. When the seats wear down from multiple cycles, the plug and seats are easily replaced without removing the valve from the pipe line. Since our seats take the wear of the plug, the body and bonnet liners last longer against the affects of abrasion, pressure, and temperature. This design of the seats gives lower operating torques for all sizes equating to numerous additional benefits including ease of turning and downsizing of actuators.

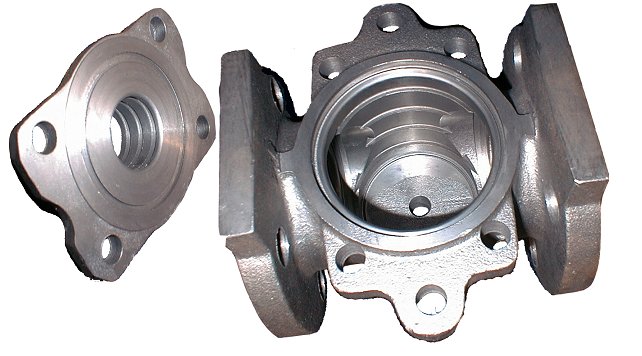

In addition, all liners are injection molded at our facility. Injection molding is a process whereby plastic resin is heated to a melt temperature and injected under pressure into the valve body, bonnet, or onto the plug. This process creates a uniformly dense thickness of heavy plastic lining ensuring no weakness in the liner. Also, they are locked into the machined dovetail grooves in the metal of the part (the locked-in lining is an excellent feature for vacuum service applications). ChemValve offers a variety of liners in PPL (polypropylene), PVDF (Kynar), PFA (perfluoroalkoxy) and GRPFA (glass reinforced PFA). Liner selection is based on the compatibility of the plastic resin to the flowing media at service temperature and pressure. ChemValve personnel are fully prepared to assist you in selecting the best liner for your application. For details about our liner options, visit our Liners web page.

In addition, all liners are injection molded at our facility. Injection molding is a process whereby plastic resin is heated to a melt temperature and injected under pressure into the valve body, bonnet, or onto the plug. This process creates a uniformly dense thickness of heavy plastic lining ensuring no weakness in the liner. Also, they are locked into the machined dovetail grooves in the metal of the part (the locked-in lining is an excellent feature for vacuum service applications). ChemValve offers a variety of liners in PPL (polypropylene), PVDF (Kynar), PFA (perfluoroalkoxy) and GRPFA (glass reinforced PFA). Liner selection is based on the compatibility of the plastic resin to the flowing media at service temperature and pressure. ChemValve personnel are fully prepared to assist you in selecting the best liner for your application. For details about our liner options, visit our Liners web page.

The ChemValve Fully Lined Plug Valve also has adjustable chevron PTFE packing. The six ring set, combined with the fully lined bonnet, is much more substantial than the thin diaphragms used in other lined plug valve designs. Consequently, this means there is little chance of either corrosive stem leakage onto the bonnet of the valve or fugitive emissions to the atmosphere.

All of these features convert directly into cost savings for the user through minimum down time and replacement costs. ChemValve has an extensive Quality Control Program that is strictly followed for each valve. For all of our products, copies of these documents can be furnished upon request.